Differential (mechanical device)

From Wikipedia, the free encyclopedia

| This article needs additional citations for verification. Please help improve this article by adding reliable references. Unsourced material may be challenged and removed. (July 2009) |

In automobiles and other wheeled vehicles, the differential allows each of the driving roadwheels to rotate at different speeds, while for most vehicles supplying equal torque to each of them.

Purpose

A vehicle's wheels rotate at different speeds, mainly when turning corners. The differential is designed to drive a pair of wheels with equal torque while allowing them to rotate at different speeds. In vehicles without a differential, such as karts, both driving wheels are forced to rotate at the same speed, usually on a common axle driven by a simple chain-drive mechanism. When cornering, the inner wheel needs to travel a shorter distance than the outer wheel, so with no differential, the result is the inner wheel spinning and/or the outer wheel dragging, and this results in difficult and unpredictable handling, damage to tires and roads, and strain on (or possible failure of) the entire drivetrain.History

There are many claims to the invention of the differential gear but it is likely that it was known, at least in some places, in ancient times. Some historical milestones of the differential include:- 1050 BC–771 BC: The Book of Song (which itself was written between 502 and 557 A.D.) makes the assertion that the South Pointing Chariot, which uses a differential gear, was invented during the Western Zhou Dynasty in China.

- 227 – 239 AD – Despite doubts from fellow ministers at court, Ma Jun from the Kingdom of Wei in China invents the first historically verifiable South Pointing Chariot, which provided cardinal direction as a non-magnetic, mechanized compass.

- 658, 666 AD – two Chinese Buddhist monks and engineers create South Pointing Chariots for Emperor Tenji of Japan.

- 1027, 1107 AD – Documented Chinese reproductions of the South Pointing Chariot by Yan Su and then Wu Deren, which described in detail the mechanical functions and gear ratios of the device much more so than earlier Chinese records.

- 1720 – Joseph Williamson uses a differential gear in a clock.

- 1810 – Rudolph Ackermann of Germany invents a four-wheel steering system for carriages, which some later writers mistakenly report as a differential.

- 1827 – modern automotive differential patented by watchmaker Onésiphore Pecqueur (1792–1852) of the Conservatoire des Arts et Métiers in France for use on a steam cart. (Sources: Britannica Online and [1])

- 1832 – Richard Roberts of England patents 'gear of compensation', a differential for road locomotives.

- 1876 – James Starley of Coventry invents chain-drive differential for use on bicycles; invention later used on automobiles by Karl Benz.

- 1897 – first use of differential on an Australian steam car by David Shearer.

- 1913 – Packard introduces the spiral-gear differential, which cuts gear noise.

- 1926 – Packard introduces the hypoid differential, which enables the propeller shaft and its hump in the interior of the car to be lowered.

- 1958 – Vernon Gleasman patents the Torsen dual-drive differential, a type of limited slip differential that relies solely on the action of gearing instead of a combination of clutches and gears.

Functional description

A cutaway drawing of a car's rear axle, showing the crown wheel and pinion of the final drive, and the smaller differential gears

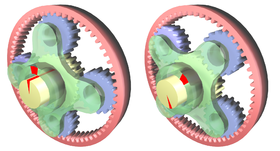

Torque is supplied from the engine, via the transmission, to a drive shaft (British term: 'propeller shaft', commonly and informally abbreviated to 'prop-shaft'), which runs to the final drive unit that contains the differential. A spiral bevel pinion gear takes its drive from the end of the propeller shaft, and is encased within the housing of the final drive unit. This meshes with the large spiral bevel ring gear, known as the crown wheel. The crown wheel and pinion may mesh in hypoid orientation, not shown. The crown wheel gear is attached to the differential carrier or cage, which contains the 'sun' and 'planet' wheels or gears, which are a cluster of four opposed bevel gears in perpendicular plane, so each bevel gear meshes with two neighbours, and rotates counter to the third, that it faces and does not mesh with. The two sun wheel gears are aligned on the same axis as the crown wheel gear, and drive the axle half shafts connected to the vehicle's driven wheels. The other two planet gears are aligned on a perpendicular axis which changes orientation with the ring gear's rotation. In the two figures shown above, only one planet gear (green) is illustrated, however, most automotive applications contain two opposing planet gears. Other differential designs employ different numbers of planet gears, depending on durability requirements. As the differential carrier rotates, the changing axis orientation of the planet gears imparts the motion of the ring gear to the motion of the sun gears by pushing on them rather than turning against them (that is, the same teeth stay in the same mesh or contact position), but because the planet gears are not restricted from turning against each other, within that motion, the sun gears can counter-rotate relative to the ring gear and to each other under the same force (in which case the same teeth do not stay in contact).

Thus, for example, if the car is making a turn to the right, the main crown wheel may make 10 full rotations. During that time, the left wheel will make more rotations because it has further to travel, and the right wheel will make fewer rotations as it has less distance to travel. The sun gears (which drive the axle half-shafts) will rotate in opposite directions relative to the ring gear by, say, 2 full turns each (4 full turns relative to each other), resulting in the left wheel making 12 rotations, and the right wheel making 8 rotations.

The rotation of the crown wheel gear is always the average of the rotations of the side sun gears. This is why, if the driven roadwheels are lifted clear of the ground with the engine off, and the drive shaft is held (say leaving the transmission 'in gear', preventing the ring gear from turning inside the differential), manually rotating one driven roadwheel causes the opposite roadwheel to rotate in the opposite direction by the same amount.

When the vehicle is traveling in a straight line, there will be no differential movement of the planetary system of gears other than the minute movements necessary to compensate for slight differences in wheel diameter, undulations in the road (which make for a longer or shorter wheel path), etc.

Loss of traction

One undesirable side effect of a conventional differential is that it can reduce overall torque – the rotational force which propels the vehicle. The amount of torque required to propel the vehicle at any given moment depends on the load at that instant – how heavy the vehicle is, how much drag and friction there is, the gradient of the road, the vehicle's momentum, and so on. For the purpose of this article, we will refer to this amount of torque as the "threshold torque".The torque applied to each driving roadwheel is a result of the engine and transmission applying a twisting force against the resistance of the traction at that roadwheel. Unless the load is exceptionally high, the engine and transmission can usually supply as much torque as necessary, so the limiting factor is usually the traction under each wheel. It is therefore convenient to define traction as the amount of torque that can be generated between the tire and the road surface, before the wheel starts to slip. If the total traction under all the driven wheels exceeds the threshold torque, the vehicle will be driven forward; if not, then one or more wheels will simply spin.

To illustrate how a differential can limit overall torque, imagine a simple rear-wheel drive vehicle, with one rear roadwheel on asphalt with good grip, and the other on a patch of slippery ice. With the load, gradient, etc., the vehicle requires, say, 2,000 newton metres (1,480 ft·lbf) of torque to move forward (i.e. the threshold torque). Let us further assume that the non-spinning traction on the ice equates to 400 N·m (300 ft·lbf), and the asphalt to 3,000 N·m (2,210 ft·lbf).

If the two roadwheels were driven without a differential, each roadwheel would be supplied with an equal amount of torque, and would push against the road surface as hard as possible. The roadwheel on ice would quickly reach the limit of traction (400 Nm), but would be unable to spin because the other roadwheel has good traction. The traction of the asphalt plus the small extra traction from the ice exceeds the threshold requirement, so the vehicle will be propelled forward.

With a differential, however, as soon as the "ice wheel" reaches 400 Nm, it will start to spin, and then develop less traction ~300 Nm. The planetary gears inside the differential carrier will start to rotate because the "asphalt wheel" encounters greater resistance. Instead of driving the asphalt wheel with more force, the differential will still symmetrically split the total amount of available torque equally. ~300 Nm is sufficient to make the ice wheel to spin, but the equal amount of ~300 Nm is not enough to turn the asphalt wheel. Since the asphalt wheel remains stationary, the spinning ice wheel will rotate twice as fast as before. As the actual torque on both roadwheels is the same – the amount is determined by the lesser traction of the ice wheel. So both wheels will get 300 Nm each. Since 600 Nm is less than the required threshold torque of 2000 Nm, the vehicle will not be able to utilise the output from the engine, and will not move.

An observer will simply see one stationary roadwheel on one side of the vehicle, and one spinning roadwheel on the opposite side. It will not be obvious that both wheels are generating the same torque (i.e. both wheels are in fact pushing equally, despite the difference in rotational speed). This has led to a widely held misconception that a vehicle with a differential is really only "one-wheel-drive". In fact, a normal differential always allows the transmission of equal torque to both driven roadwheels; unless it is a specific type of differential, such as locking, torque-biasing, or limited slip type.

A proposed way to distribute the power to the wheels, is to use the concept of gearless differential, of which a review has been reported by Provatidis [1], but the various configurations seem to correspond either to the "sliding pins and cams" type, such as the ZF B-70 available for early VWs, or are a variation of the ball differential.

Traction-aiding devices

| | This section may contain original research. Please improve it by verifying the claims made and adding references. Statements consisting only of original research may be removed. More details may be available on the talk page. (July 2009) |

- One solution is the limited slip differential (LSD), the most well-known of which is the clutch-type LSD. With this differential, the side gears are coupled to the carrier via a multi-disc clutch which allows extra torque to be sent to the wheel with high resistance than available at the other driven roadwheel when the limit of friction is reached at that other wheel. Below the limit of friction more torque goes to the slower (inside) wheel. If there is no load on one wheel then no torque goes to the other so the LSD provides no torque except for spring loading, but some extra effect can be obtained by partially applying the vehicle's parking brake when one roadwheel is spinning, as this can provide some resistance there to increase the overall torque, and allow the other driven roadwheel to move the vehicle. This only works where the handbrake acts on the driven wheels, as in the traditional rear-wheel drive layout. Naturally, the handbrake should be released as soon as the vehicle is moving again.

- A locking differential, such as ones using differential gears in normal use but using air or electrically controlled mechanical system, which when locked allow no difference in speed between the two wheels on the axle. They employ a mechanism for allowing the planetary gears to be locked relative to each other, causing both wheels to turn at the same speed regardless of which has more traction; this is equivalent to effectively bypassing the differential gears entirely. Other locking systems may not even use differential gears but instead drive one wheel or both depending on torque value and direction.

- A high-friction 'Automatic Torque Biasing' (ATB) differential, such as the Torsen differential, where the friction is between the gear teeth rather than at added clutches. This applies more torque to the driven roadwheel with highest resistance (grip or traction) than is available at the other driven roadwheel when the limit of friction is reached at that other wheel. When tested with the wheels off the ground, if one wheel is rotated with the differential case held, the other wheel will still rotate in the opposite direction as for an open differential but there with be some frictional losses and the torque will be distributed at other than 50/50. Although marketed as being "torque-sensing", it functions the same as a limited slip differential.

- A very high-friction differential, such as the ZF "sliding pins and cams" type, so that there is locking from very high internal friction. When tested with the wheels off the ground with torque applied to one wheel it will lock, but it is still possible for the differential action to occur in use, albeit with considerable frictional losses, and with the road loads at each wheel in opposite directions rather than the same (acting with a "locking and releasing" action rather than a distributed torque).

- An additional function of the conventional electronic traction control systems usually use the anti-lock braking system (ABS) roadwheel speed sensors to detect a spinning roadwheel, and apply the brake to that wheel. This progressively raises the reaction torque at that roadwheel, and the differential compensates by transmitting more torque through the other roadwheel – the one with better traction. In Volkswagen Group vehicles, this specific function is called 'Electronic Differential Lock' (EDL).

- In a four-wheel drive vehicle, a viscous coupling unit can replace a centre differential entirely, or be used to limit slip in a conventional 'open' differential. It works on the principle of allowing the two output shafts to counter-rotate relative to each other, by way of a system of slotted plates that operate within a viscous fluid, often silicone. The fluid allows slow relative movements of the shafts, such as those caused by cornering, but will strongly resist high-speed movements, such as those caused by a single wheel spinning. This system is similar to a limited slip differential.

4WD vehicles without a centre differential should not be driven on dry, paved roads in four-wheel drive mode, as small differences in rotational speed between the front and rear wheels cause a torque to be applied across the transmission. This phenomenon is known as "wind-up", and can cause considerable damage to the transmission or drive train. On loose surfaces these differences are absorbed by the tire slippage on the road surface.

A transfer case may also incorporate a centre differential, allowing the drive shafts to spin at different speeds. This permits the four-wheel drive vehicle to drive on paved surfaces without experiencing "wind-up".

Epicyclic differential

Epicyclic gearing is used here to apportion torque asymmetrically. The input shaft is the green hollow one, the yellow is the low torque output, and the pink is the high torque output. The force applied in the yellow and the pink gears is the same, but since the arm of the pink one is 2×–3× as big, the torque will be 2×–3× as high.

Epicyclic gears are also called planetary gears because the axes of the planet gears revolve around the common axis of the sun and ring gears that they mesh with and roll between. In the image, the yellow shaft carries the sun gear which is almost hidden. The blue gears are called planet gears and the pink gear is the ring gear or annulus.

Spur-gear differential

This is another type of differential that was used in some early automobiles, more recently the Oldsmobile Toronado, as well as other non-automotive applications. It consists of spur gears only.A spur-gear differential has two equal-sized spur gears, one for each half-shaft, with a space between them. Instead of the Bevel gear, also known as a miter gear, assembly (the "spider") at the centre of the differential, there is a rotating carrier on the same axis as the two shafts. Torque from a prime mover or transmission, such as the drive shaft of a car, rotates this carrier.

Mounted in this carrier are one or more pairs of identical pinions, generally longer than their diameters, and typically smaller than the spur gears on the individual half-shafts. Each pinion pair rotates freely on pins supported by the carrier. Furthermore, the pinions pairs are displaced axially, such that they mesh only for the part of their length between the two spur gears, and rotate in opposite directions. The remaining length of a given pinion meshes with the nearer spur gear on its axle. Therefore, each pinion couples that spur gear to the other pinion, and in turn, the other spur gear, so that when the drive shaft rotates the carrier, its relationship to the gears for the individual wheel axles is the same as that in a miter-gear differential.

Non-automotive applications

A differential gear train can also be used to allow a difference between two input axles. Mills often used such gears to apply torque in the required axis. It's also used in fine mechanical watches with a hand to show the amount of reserve power in the mainspring.The oldest known example of a differential was once thought to be in the Antikythera mechanism. It was supposed to have used such a train to produce the difference between two inputs, one input related to the position of the sun on the zodiac, and the other input related to the position of the moon on the zodiac; the output of the differential gave a quantity related to the moon's phase. It has now been proven that the assumption of the existence of a differential gearing arrangement was incorrect.[2]

In the first half of the twentieth century, mechanical analog computers, called differential analyzers, were constructed that used differential gear trains to perform addition and subtraction. The U.S. Navy Mk.1 gun fire control computer used about 160 differentials of the miter gear type.

Differentials, usually flat but also spherical, are used in wristwatches to allow the power reserve to be indicated. Power from the mainspring is split via the differential to the time indications and the power reserve indicator. Differentials are also used in watchmaking to link two separate regulating systems with the aim of averaging out errors. Greubel Forsey use a spherical differential to link two double tourbillon systems in their Quadruple Differential Tourbillon.

Active differentials

A relatively new technology is the electronically-controlled 'active differential'. An electronic control unit (ECU) uses inputs from multiple sensors, including yaw rate, steering input angle, and lateral acceleration – and adjusts the distribution of torque to compensate for undesirable handling behaviours like understeer. Active differentials used to play a large role in the World Rally Championship, but in the 2006 season the FIA has limited the use of active differentials only to those drivers who have not competed in the World Rally Championship in the last five years.Fully integrated active differentials are used on the Ferrari F430, Mitsubishi Lancer Evolution, and on the rear wheels in the Acura RL. A version manufactured by ZF is also being offered on the latest Audi S4 and Audi A4[3].

The second constraint of the differential is passive – it is actuated by the friction kinematics chain through the ground. The difference in torque on the roadwheels and tires (caused by turns or bumpy ground) drives the second degree of freedom, (overcoming the torque of inner friction) to equalise the driving torque on the tires. The sensitivity of the differential depends on the inner friction through the second degree of freedom. All of the differentials (so called “active” and “passive”) use clutches and brakes for restricting the second degree of freedom, so all suffer from the same disadvantage – decreased sensitivity to a dynamically changing environment. The sensitivity of the ECU controlled differential is also limited by the time delay caused by sensors and the response time of the actuators.

See also

- Ball differential

- Limited Slip Differential

- Locking differential

- Whippletree (mechanism), which evenly divides force as a differential divides torque.

- Aron's electricity meter, an early electricity meter, relying on the use of a mechanical differential.

References

- ^ Provatidis, Christopher, G. (2003). "A critical presentation of Tsiriggakis’ gearless differential". Mobility & Vehicles Mechanics 29 (4): 25–46; also at http://www.tsiriggakis.com/gd.html

- ^ Wright, M T. (2005). "The Antikythera Mechanism and the early history of the Moon Phase Display". Antiquarian Horology 29 (3 (March 2006)): 319–329.

- ^ "ZF Press release"

External links

| Wikimedia Commons has media related to: Automobile differentials |

- An article explaining differentials with illustrations and video

- "Around the Corner", 1937 Jam Handy film made for Chevrolet explains very clearly how an open differential works.

- "Tsiriggakis' Gearless Differential", http://www.tsiriggakis.gr

ไม่มีความคิดเห็น:

แสดงความคิดเห็น